When it comes to air purification technologies, the decision doesn’t always have to be either/or. Most technologies are best in pairs. ActivePure’s portable plug-and-play units contain multiple complementary technologies, including a HEPA filter, an Activated Carbon filter, and, of course, ActivePure Technology. We’ve written about HEPA filters before, but we’ve yet to do a deep dive on Activated Carbon. Here’s why ActivePure is such an appropriate complement to an Activated Carbon filter.

What Is Activated Carbon? How Does Activated Carbon Work?

Activated Carbon (sometimes called activated charcoal) is the most famous adsorbent material. Adsorbent (not to be confused with absorbent) materials attract molecules to their surface. Activated Carbon accomplishes this without chemical change (i.e., physisorption). How? The random movement of fluid molecules bouncing against each other (Brownian motion) forces them to collide with the carbon. The contaminant molecules then release energy (called the heat of adsorption) and don’t have enough leave again on their own. This is because a weak electrostatic charge (the van der Waals forces) takes over and holds them there.

To put the physics vocabulary aside, molecular contaminants stick to Activated Carbon’s surface. When it comes to air purification, this is used to collect gases such as volatile organic compounds (VOC gases) and odors.

What makes carbon “activated” is treating it with heat. Heating a carbon source (such as coal, coconut, or bamboo) the proper way creates a charcoal with many tiny little pores. These pores increase the surface area of the carbon; more surface area means more unwanted gas molecules can be captured.

Advantages of Activated Carbon

Activated Carbon has several key benefits as a purification source:

- First, it is a well-tested and well-trusted source of VOC gas removal. Unlike many other technologies, it has a high rate of removal in a single pass.

- Second, it can be created out of sustainable and affordable materials; per a review of cleaning technologies published in Environments, “[Activated Carbon] can be produced from agricultural wastes such as sugarcane bagasse, apple pomace or coconut shell[...]”

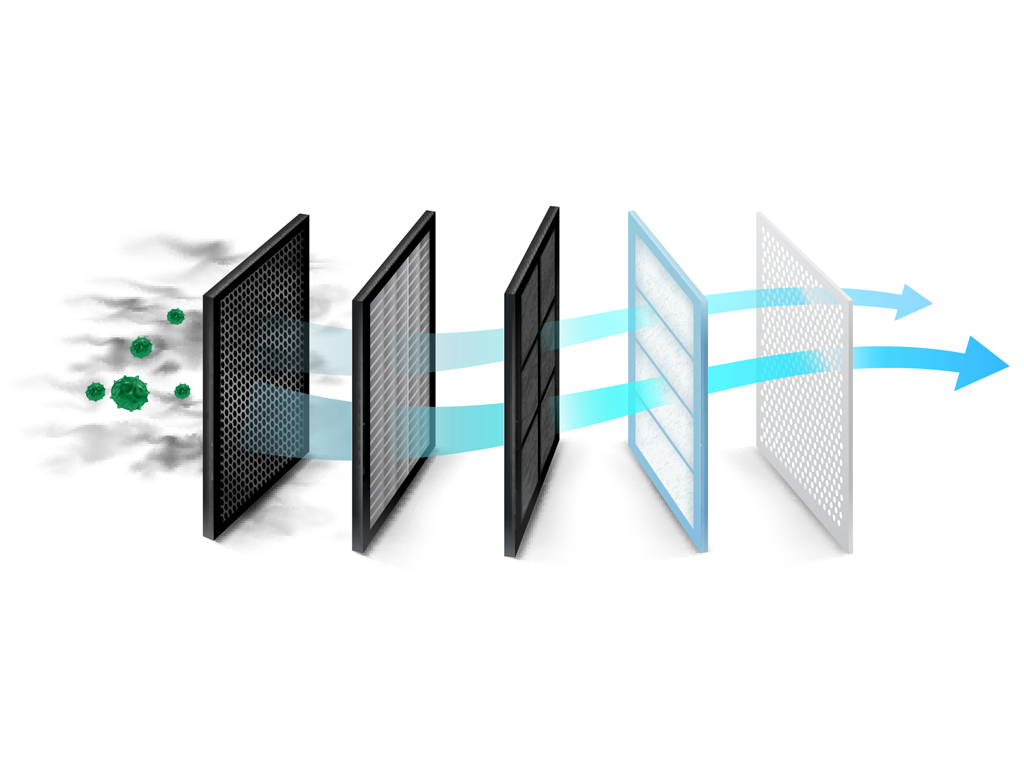

- Third, it has the versatility to be used in multiple environments. Industrial filters often involve a bed of packed carbon pellets. Water filtration might involve a cylinder of carbon mesh. In home filtration systems, Activated Carbon is often a simple rectangular screen installed behind the HEPA filter or infused or placed within the HEPA filter.

Disadvantages of Activated Carbon

All of the disadvantages of Activated Carbon come down to one simple fact: it is a physical process, not a chemical change. This leads to several difficulties:

-

First, the life of an Activated Carbon filter varies widely depending on the amount of carbon it contains. Eventually, Activated Carbon runs out of surface for contaminants to stick to. But how fast this surface fills up depends on how well the original medium was treated, how many contaminants pass through it, whether the airflow allows contaminants to reach all parts of the filter, the airflow speed, the humidity, and the temperature. All this adds up to a maintenance schedule which is, at best, a guess.

- Related to the above, one VOC gas can also displace another. One EPA paper provides this example; “incoming toluene will cause the displacement of isobutanol as the toluene occupies the sorption site.” This is because contaminants with a higher molecular weight or lower vapor pressure can displace contaminants with a lower molecular weight and higher vapor pressure. As a different the EPA paper summarizes, “Thus, during the course of the adsorption cycle the carbon’s capacity for a higher vapor pressure constituent decreases.”

- Second, Activated Carbon does not neutralize pathogens. However, pathogens can flourish in the carbon-rich, high-humidity environment of the filter. As the aforementioned paper from Environments reads, “A negative feature of the adsorption technology is the possibility of the deposition and development of airborne bacteria on the adsorbent surface due to the high biocompatibility of these materials.”

- Third, under the right circumstances, contaminants can be re-released back into the air. Extreme temperature changes add energy which allow the molecules to defeat van der Waals (albeit this does not appear to be a significant risk under normal circumstances). More relevant to the average homeowner, a reduction in airborne contaminant concentration can essentially suck VOC gases off the filter and back into the air; this equalization is referred to as the concentration gradient driving force.

You Don’t Have to Choose Just One

There is a simple way to fix these disadvantages — pair Activated Carbon with ActivePure Technology. ActivePure Technology’s scrubbing molecules don’t just purify the air; they also keep pathogens from thriving on the Activated Carbon screen. Meanwhile, any VOC gases the filter accidentally releases are in the perfect position to be neutralized by the ActivePure cell, not to mention the lower amount of gases making it to the carbon to begin with due to ActivePure neutralizing them while still airborne in the indoor space. Of course, you’ll still have to replace your Activated Carbon filter occasionally (not even we can prevent routine maintenance) but that maintenance should be minimized with the aid of other technologies working in conjunction.

Say you don’t want or can’t use a portable air purifier; can ActivePure assist the carbon filter in your HVAC? Of course we can! Discover the benefits of layered HVAC protections with our partner’s induct unit: the Air Scrubber with ActivePure Technology.