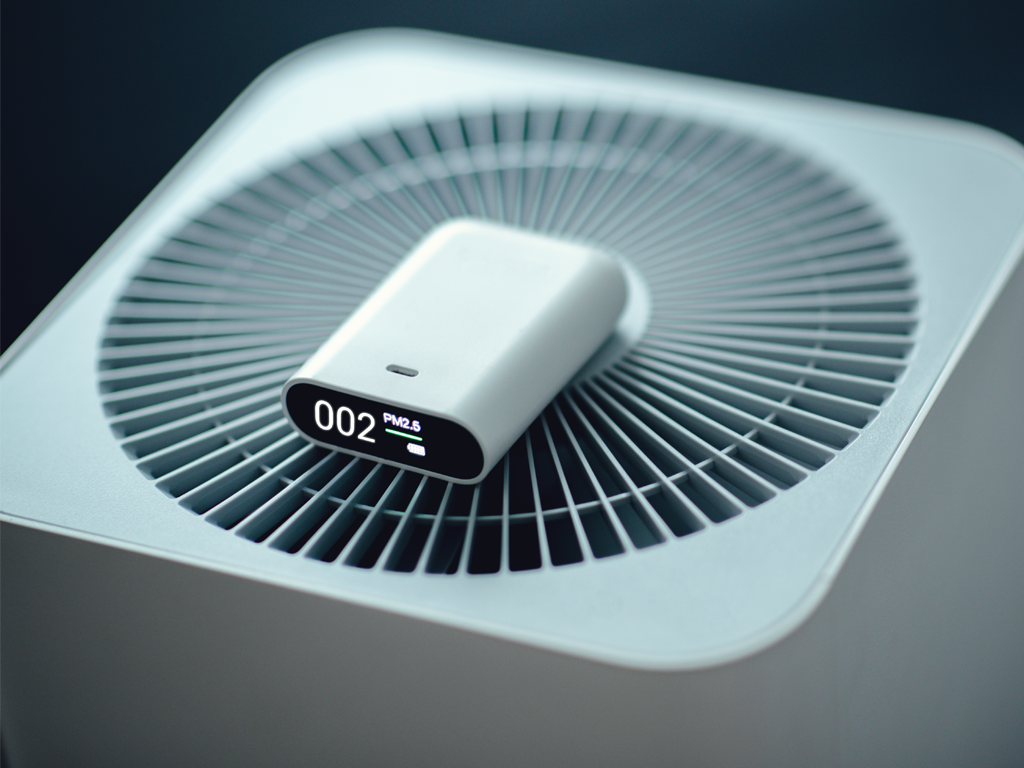

Since ActivePure began offering real-time air quality monitors to our customers, we’ve already seen how real-time air quality testing benefits building residents. But air quality monitoring benefits building owners too (whether those owners are towering companies or scrappy small businesses). Here are 7 ways you can use real-time indoor air quality (IAQ) testing data to help the bottom line.

1. Compare IAQ Data to Sick Days

Real-time air quality data can help you identify if indoor air pollution is causing you or your employees to miss work.

For instance, both mold and bacteria seem to thrive and spread best in humid environments, exacerbating allergies and triggering office outbreaks. Tracking your humidity in real time helps keep it at an optimum level.

Another contaminant — particulate matter (PM) — has also been linked to absenteeism. According to one study of K-12 schools, “even PM2.5 and ozone exposure below the air quality index breakpoints for good air quality (<12.1 μg m−3 and <55 ppb, respectively) was associated with positive rate ratios of absences: 1.04 per μg m−3 and 1.01 per ppb increase, respectively.” (In other words, even when air quality guidelines are met, a single part per billion increase in air pollution still hurts student attendance.)

Adults are similarly affected. Per an analysis of 18 different workplace studies, “Associations between pollutants and restricted activity days in time-series studies of short-term exposures, measured as work-loss days, school-loss days, or both were significant for PM10[…]and PM2.5[…].” By tracking PM in real time, your organization can see if there is room for improvement.

All this missed time adds up. As we reported in a previous blog, “the cost of sick leave due to poor building ventilation and indoor environmental quality [...]cost employers $840 per employee per year or $40 billion” nationally. Similarly, the aforementioned school study estimates that “Reducing pollution by 50% would save $426,000 per year” in the analyzed district.”

2. Compare IAQ Data to Productivity

Perhaps more endemic than absenteeism, poor air quality affects resident comfort and cognition — and thus affects productivity. Per ActivePure partner Sanalife, “Studies have shown that inadequate IAQ can lead to fatigue, headaches, and difficulties concentrating.” Poor air quality (especially CO2 levels) can also reduce cognition speed.

But you don’t have to take our word for it. According to one Danish study, “It was shown in realistic experimental exposures lasting up to 5 [hours] that the performance of simulated office work could be significantly increased by removing common indoor sources of air pollution[...]These short-term effects were demonstrated repeatedly even at pollutant levels that had no measurable effects on the perception of air quality by the occupants themselves[…]” (emphasis ours). Such improvements increased productivity by 6-9%, allowing an ROI on contaminant reduction efforts within 2 years.

An article published by the think-tank IZA World of Labor agrees; “Evidence suggests that improvements in air quality lead to improvements in worker productivity at the micro level across a range of sectors, including agriculture, manufacturing, and the service sectors, as well as at more aggregate macro levels.”

3. Narrow Down Where and When Problems Are Occurring

Of course, you can’t improve productivity via IAQ adjustments if you don’t know what is wrong. Knowing which pollutant is causing the issue, where it’s appearing in the building, and when it’s at its highest concentration can provide invaluable insights. For instance, if your monitor shows spiking PM levels in Exam Room 1 every day around lunch, you might uncover a ventilation backflow between that exam room and the hospital cafeteria. If it shows spiking CO2 levels during the night shift, you might need to increase ventilation. Without real-time data across locations, however, your IAQ troubleshooting is nothing but a shot in the dark.

4. Reduce Unnecessary Interventions

Real-time testing data isn’t just helpful for fixing problems; it can also identify unnecessary expenditures, especially in the area of energy. As the aforementioned Danish study puts it, “It is usually more energy-efficient to eliminate sources of pollution than to increase outdoor air supply rates.” For instance, there’s no need to run the HVAC fan at high speed to flush PM if CO2 levels are sufficiently low; portable air cleaners might be a more energy-efficient option.

Real-time data can also let you know if air quality complaints are about air quality at all. One Portuguese study found that “Poor lighting and acoustical quality have also been associated with malaise and physiological stress among office workers.” In other words, there’s no need to buy extra portable air filters when the glaring fluorescent lights are really to blame.

5. Guide Renovation Priorities

In contrast, some buildings may need to focus more on ventilation, not less. Per the EPA, “Weatherization and other energy efficiency upgrades can have negative impacts on occupant health and safety if not accompanied by appropriate indoor air quality[…]protections.” This is because attempts to make a building more energy efficient often seal pollutants inside and allow carbon dioxide to build to undesirable levels. Tracking IAQ in real-time can tell you if your energy upgrades are having a negative impact, helping you balance between the energy budget and ventilation.

6. Get Ahead of Future Standards

The halting and haphazard adaption of ASHRAE Standard 241 suggests that private businesses aren’t going to be allowed to set their own air quality standards indefinitely. We predict the federal government will step in with universal mandatory IAQ regulations at some point in the future. Thus, monitoring your own air quality will help you know where you stand when said standards arrive.

Even if the government doesn’t step in, real-time monitoring can help you see how close you are to qualifying for certain desirable building certifications, such as LEED. Buildings following “healthy” standards are often able to charge 4-8% more per square foot.

7. Aim for Automation

Thanks to the rapid pace of AI development, your building can learn when to turn the lights off, when to increase ventilation, when to adjust temperature and humidity, and when to run air cleaners — all by itself! Such automated interventions, however, require real-time air quality data. Not every building owner is comfortable with this lack of manual control. Those that are, though, can uncover energy savings of 20-62% per year.

If you’re not ready for such radical automation yet, don’t worry. ActivePure sources bespoke air quality solutions for each customer according to your needs and budget. Whether you are seeking an integrated sensor suite or al-la-carte options, let us start crafting your individual air quality plan today.